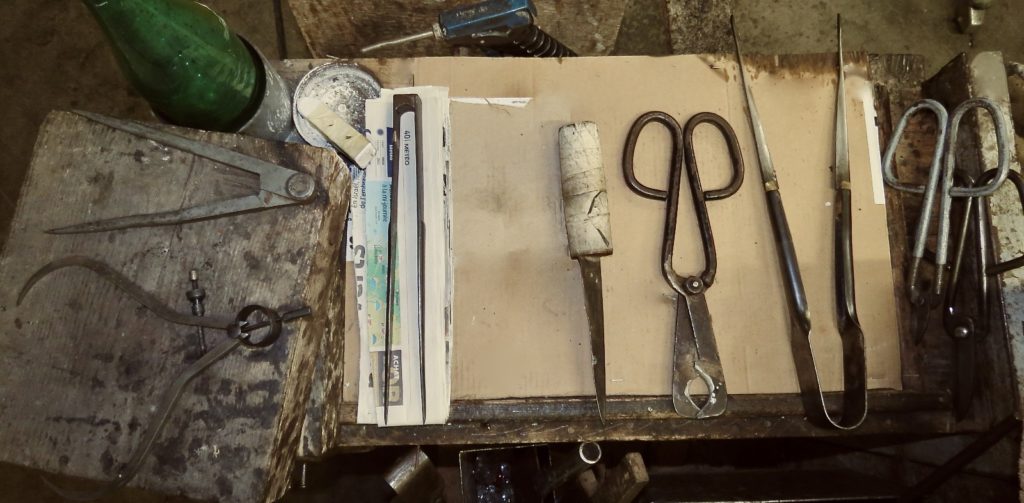

The workshop of a craftsman glassblower

Our workshop

In glassware, we work with numerous and diverse tools but here is a list of the main :

- the rods : tubes in steel of different diameters they permit to “gather” the glass from the melting furnace. There are three types : the blowpipes (hollow), the punty and the rods (full).

- the marver : table or surface on which glassblowers shape hot glass with a blowpipe.

In glassblowing, we also use molds : they are useful to give a shape, more or less precise, whether it is round, chubby or cylindrical. We have a stock of all sizes and shapes for our pieces but also some that have been made on demand for unique objects or reproductions. The molds are made of wood or steel, reusable with maintenance.

Our furnaces

We work the glass at about 1100 degrees celsius and it is kept in a melting furnace. We made our glass from sand, soda ash and carbonate of lime. These three elements are mixed up with a large quantity of clear recycled glass (bottles, pots,…) and is put in the melting furnace heated up to 1300 degrees celsius. At this temperature, sand turn into glass and mix with recycled glass. This process takes one day long and require to fill in the furnace little by little with this mix.

Then, there is the reheating furnace, used to heat again the glass to a workable temperature because as the glass is very sensible to temperature changes, he solidifies in few minutes. In order to shape the glass, we have to heat it between each handling.

Finally, the annealer. In fact, we can’t let the glass cool in the open air, because of the temperature difference it would end cracking up in reaction to the thermal shock. Each piece need, after being shaped, to be slowly cooked in a furnace that stabilise the glass at 500 degrees before progressively going down in temperature.

After these short explanations and a quick presentation of our workshop, please feel free to come discover our job in practice.